Formsprag clutch

Posted: Thu Apr 22, 2010 9:18 pm

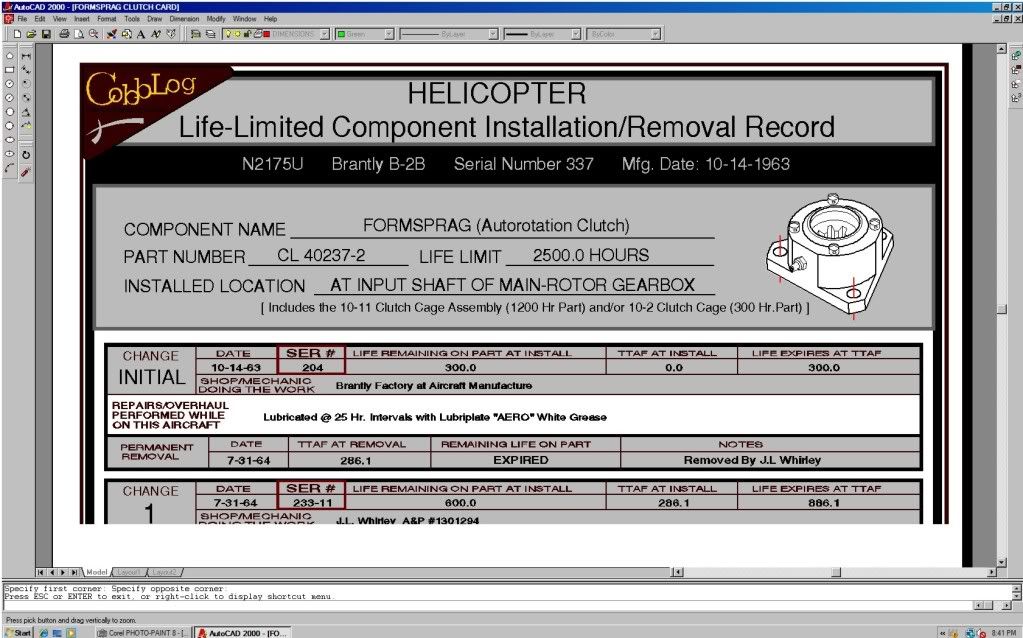

It's obvious that the Formsprag clutch is critical to flight safety. Read the report below(I removed the references to the N number otherwise it's a direct copy and paste). Given this importance can anyone give any thoughts on checking this thing? Does anybody have a -3 and actually compared it to a -2? I don't know how many 40237-3 there are out there. Mine is a 40237-2 and every one I've seen in time component lists has been the -2. One observation I make on the below report-I think there is an error in the report when asked if the Helicopter manufacturer recommended the new style -3 the report said "they did not". I think they meant to say that while -3 was the current production recommended part the older -2 was still a legal and acceptable part for the B2b. They did clarify that somewhat but the part about NOT recommending the new style -3 doesn't make sense in the context of the paragraph(after all it is the new, improved, positive engagement clutch according to the report).

"On April 19, 1995, at 1630 central daylight time (cdt), a Brantly B-2B piloted by a

private pilot, was substantially damaged when it rolled over during an off airport landing on soft

ground. The pilot stated the helicopter's power clutch failed during cruise requiring him to

auto-rotate to a forced landing. Visual meteorological conditions prevailed at the time of the

accident. The 14 CFR Part 91 ferry flight was not operating on a flight plan. The pilot and

passenger reported no injuries. The flight had departed Strother, Kansas, 1610 cdt.

According to the pilot's written statement attached to NTSB Form 6120.1/2, "All was normal. Engine

RPM was 2900, altitude was approximately 500 feet AGL, and indicated airspeed was 80 MPH." During

the flight the engine RPM "...suddenly and rapidly increased as if the engine was abruptly

unloaded...", according to the pilot. He said he auto-rotated to a landing that was quite smooth.

After touching down the pilot said the helicopter slid on the field's muddy surface and rolled over

onto its right side.

An eye witness said he observed the helicopter "...come down too fast, everything looked and

sounded ok, just going too fast. The helicopter landed, bounced off the ground and rolled over on

its side." Two other eye witnesses said they observed the helicopter descending very rapidly.

The on-scene investigation revealed that the helicopter's over- running clutch unit had failed. A

mechanic helping with the inspection stated the sprag tangs inside the clutch assembly

had failed. He said the wear pattern on the tangs appeared as though it had been under-greased

early in its service life. The mechanic said there was adequate grease in the assembly when he

looked at it.

According to a March 29, 1994, airframe maintenance logbook entry, an over-running clutch assembly,

serial number 93, was installed on the Brantly B2b. At that it had a total airframe time of 833.8

hours. The clutch assembly had 353.2 hours on when it was installed on the B2b. The helicopter had

operated about 129 hours with the clutch before it failed. The helicopter maintenance manual

stated the clutch assembly "...must be returned to Brantly Helicopter Industries (BHI) for

engineering evaluation, inspection, and overhaul as required at each 600-hour interval." The

manual stated the clutch assembly's total accumulated service time is not to exceed 2,500 hours.

The over-running clutch assembly (clutch assembly) was dismantled at the manufacturer. An FAA

Principal Maintenance Inspector (PMI) represented the NTSB during the clutch assembly's inspection.

The clutch assembly had a part number of 40237- 2 and had been rebuilt on October 13,1964.

Examination revealed the sprags in the clutch had been worn beyond the

manufacturer's limits. The PMI said the assembly's inner and outer races were also worn beyond the

manufacturer's limits. According to the PMI, the worn parts allowed the clutch to go over-center

and become disengaged.

The manufacturer of the clutch assembly said a new style clutch assembly had been produced and

superseded the 40237-2. The new clutch assembly has a part number of 40237-3. The new

clutch assembly is described as a positive, continuous, engagement over-running clutch, according

to the PMI.

The helicopter manufacturer was contacted and asked if they recommended the new clutch assembly be

installed on the helicopter. A representative from the manufacturer said they did not, and advise

those seeking a new clutch assembly that a new -3 model is what is available. She said the -3

clutch assembly is FAA approved. She said the older -2 type clutch assembly is still a usable item

for the helicopter."

"On April 19, 1995, at 1630 central daylight time (cdt), a Brantly B-2B piloted by a

private pilot, was substantially damaged when it rolled over during an off airport landing on soft

ground. The pilot stated the helicopter's power clutch failed during cruise requiring him to

auto-rotate to a forced landing. Visual meteorological conditions prevailed at the time of the

accident. The 14 CFR Part 91 ferry flight was not operating on a flight plan. The pilot and

passenger reported no injuries. The flight had departed Strother, Kansas, 1610 cdt.

According to the pilot's written statement attached to NTSB Form 6120.1/2, "All was normal. Engine

RPM was 2900, altitude was approximately 500 feet AGL, and indicated airspeed was 80 MPH." During

the flight the engine RPM "...suddenly and rapidly increased as if the engine was abruptly

unloaded...", according to the pilot. He said he auto-rotated to a landing that was quite smooth.

After touching down the pilot said the helicopter slid on the field's muddy surface and rolled over

onto its right side.

An eye witness said he observed the helicopter "...come down too fast, everything looked and

sounded ok, just going too fast. The helicopter landed, bounced off the ground and rolled over on

its side." Two other eye witnesses said they observed the helicopter descending very rapidly.

The on-scene investigation revealed that the helicopter's over- running clutch unit had failed. A

mechanic helping with the inspection stated the sprag tangs inside the clutch assembly

had failed. He said the wear pattern on the tangs appeared as though it had been under-greased

early in its service life. The mechanic said there was adequate grease in the assembly when he

looked at it.

According to a March 29, 1994, airframe maintenance logbook entry, an over-running clutch assembly,

serial number 93, was installed on the Brantly B2b. At that it had a total airframe time of 833.8

hours. The clutch assembly had 353.2 hours on when it was installed on the B2b. The helicopter had

operated about 129 hours with the clutch before it failed. The helicopter maintenance manual

stated the clutch assembly "...must be returned to Brantly Helicopter Industries (BHI) for

engineering evaluation, inspection, and overhaul as required at each 600-hour interval." The

manual stated the clutch assembly's total accumulated service time is not to exceed 2,500 hours.

The over-running clutch assembly (clutch assembly) was dismantled at the manufacturer. An FAA

Principal Maintenance Inspector (PMI) represented the NTSB during the clutch assembly's inspection.

The clutch assembly had a part number of 40237- 2 and had been rebuilt on October 13,1964.

Examination revealed the sprags in the clutch had been worn beyond the

manufacturer's limits. The PMI said the assembly's inner and outer races were also worn beyond the

manufacturer's limits. According to the PMI, the worn parts allowed the clutch to go over-center

and become disengaged.

The manufacturer of the clutch assembly said a new style clutch assembly had been produced and

superseded the 40237-2. The new clutch assembly has a part number of 40237-3. The new

clutch assembly is described as a positive, continuous, engagement over-running clutch, according

to the PMI.

The helicopter manufacturer was contacted and asked if they recommended the new clutch assembly be

installed on the helicopter. A representative from the manufacturer said they did not, and advise

those seeking a new clutch assembly that a new -3 model is what is available. She said the -3

clutch assembly is FAA approved. She said the older -2 type clutch assembly is still a usable item

for the helicopter."