Formsprag clutch

Moderator: Paul Sehorne

Formsprag clutch

It's obvious that the Formsprag clutch is critical to flight safety. Read the report below(I removed the references to the N number otherwise it's a direct copy and paste). Given this importance can anyone give any thoughts on checking this thing? Does anybody have a -3 and actually compared it to a -2? I don't know how many 40237-3 there are out there. Mine is a 40237-2 and every one I've seen in time component lists has been the -2. One observation I make on the below report-I think there is an error in the report when asked if the Helicopter manufacturer recommended the new style -3 the report said "they did not". I think they meant to say that while -3 was the current production recommended part the older -2 was still a legal and acceptable part for the B2b. They did clarify that somewhat but the part about NOT recommending the new style -3 doesn't make sense in the context of the paragraph(after all it is the new, improved, positive engagement clutch according to the report).

"On April 19, 1995, at 1630 central daylight time (cdt), a Brantly B-2B piloted by a

private pilot, was substantially damaged when it rolled over during an off airport landing on soft

ground. The pilot stated the helicopter's power clutch failed during cruise requiring him to

auto-rotate to a forced landing. Visual meteorological conditions prevailed at the time of the

accident. The 14 CFR Part 91 ferry flight was not operating on a flight plan. The pilot and

passenger reported no injuries. The flight had departed Strother, Kansas, 1610 cdt.

According to the pilot's written statement attached to NTSB Form 6120.1/2, "All was normal. Engine

RPM was 2900, altitude was approximately 500 feet AGL, and indicated airspeed was 80 MPH." During

the flight the engine RPM "...suddenly and rapidly increased as if the engine was abruptly

unloaded...", according to the pilot. He said he auto-rotated to a landing that was quite smooth.

After touching down the pilot said the helicopter slid on the field's muddy surface and rolled over

onto its right side.

An eye witness said he observed the helicopter "...come down too fast, everything looked and

sounded ok, just going too fast. The helicopter landed, bounced off the ground and rolled over on

its side." Two other eye witnesses said they observed the helicopter descending very rapidly.

The on-scene investigation revealed that the helicopter's over- running clutch unit had failed. A

mechanic helping with the inspection stated the sprag tangs inside the clutch assembly

had failed. He said the wear pattern on the tangs appeared as though it had been under-greased

early in its service life. The mechanic said there was adequate grease in the assembly when he

looked at it.

According to a March 29, 1994, airframe maintenance logbook entry, an over-running clutch assembly,

serial number 93, was installed on the Brantly B2b. At that it had a total airframe time of 833.8

hours. The clutch assembly had 353.2 hours on when it was installed on the B2b. The helicopter had

operated about 129 hours with the clutch before it failed. The helicopter maintenance manual

stated the clutch assembly "...must be returned to Brantly Helicopter Industries (BHI) for

engineering evaluation, inspection, and overhaul as required at each 600-hour interval." The

manual stated the clutch assembly's total accumulated service time is not to exceed 2,500 hours.

The over-running clutch assembly (clutch assembly) was dismantled at the manufacturer. An FAA

Principal Maintenance Inspector (PMI) represented the NTSB during the clutch assembly's inspection.

The clutch assembly had a part number of 40237- 2 and had been rebuilt on October 13,1964.

Examination revealed the sprags in the clutch had been worn beyond the

manufacturer's limits. The PMI said the assembly's inner and outer races were also worn beyond the

manufacturer's limits. According to the PMI, the worn parts allowed the clutch to go over-center

and become disengaged.

The manufacturer of the clutch assembly said a new style clutch assembly had been produced and

superseded the 40237-2. The new clutch assembly has a part number of 40237-3. The new

clutch assembly is described as a positive, continuous, engagement over-running clutch, according

to the PMI.

The helicopter manufacturer was contacted and asked if they recommended the new clutch assembly be

installed on the helicopter. A representative from the manufacturer said they did not, and advise

those seeking a new clutch assembly that a new -3 model is what is available. She said the -3

clutch assembly is FAA approved. She said the older -2 type clutch assembly is still a usable item

for the helicopter."

"On April 19, 1995, at 1630 central daylight time (cdt), a Brantly B-2B piloted by a

private pilot, was substantially damaged when it rolled over during an off airport landing on soft

ground. The pilot stated the helicopter's power clutch failed during cruise requiring him to

auto-rotate to a forced landing. Visual meteorological conditions prevailed at the time of the

accident. The 14 CFR Part 91 ferry flight was not operating on a flight plan. The pilot and

passenger reported no injuries. The flight had departed Strother, Kansas, 1610 cdt.

According to the pilot's written statement attached to NTSB Form 6120.1/2, "All was normal. Engine

RPM was 2900, altitude was approximately 500 feet AGL, and indicated airspeed was 80 MPH." During

the flight the engine RPM "...suddenly and rapidly increased as if the engine was abruptly

unloaded...", according to the pilot. He said he auto-rotated to a landing that was quite smooth.

After touching down the pilot said the helicopter slid on the field's muddy surface and rolled over

onto its right side.

An eye witness said he observed the helicopter "...come down too fast, everything looked and

sounded ok, just going too fast. The helicopter landed, bounced off the ground and rolled over on

its side." Two other eye witnesses said they observed the helicopter descending very rapidly.

The on-scene investigation revealed that the helicopter's over- running clutch unit had failed. A

mechanic helping with the inspection stated the sprag tangs inside the clutch assembly

had failed. He said the wear pattern on the tangs appeared as though it had been under-greased

early in its service life. The mechanic said there was adequate grease in the assembly when he

looked at it.

According to a March 29, 1994, airframe maintenance logbook entry, an over-running clutch assembly,

serial number 93, was installed on the Brantly B2b. At that it had a total airframe time of 833.8

hours. The clutch assembly had 353.2 hours on when it was installed on the B2b. The helicopter had

operated about 129 hours with the clutch before it failed. The helicopter maintenance manual

stated the clutch assembly "...must be returned to Brantly Helicopter Industries (BHI) for

engineering evaluation, inspection, and overhaul as required at each 600-hour interval." The

manual stated the clutch assembly's total accumulated service time is not to exceed 2,500 hours.

The over-running clutch assembly (clutch assembly) was dismantled at the manufacturer. An FAA

Principal Maintenance Inspector (PMI) represented the NTSB during the clutch assembly's inspection.

The clutch assembly had a part number of 40237- 2 and had been rebuilt on October 13,1964.

Examination revealed the sprags in the clutch had been worn beyond the

manufacturer's limits. The PMI said the assembly's inner and outer races were also worn beyond the

manufacturer's limits. According to the PMI, the worn parts allowed the clutch to go over-center

and become disengaged.

The manufacturer of the clutch assembly said a new style clutch assembly had been produced and

superseded the 40237-2. The new clutch assembly has a part number of 40237-3. The new

clutch assembly is described as a positive, continuous, engagement over-running clutch, according

to the PMI.

The helicopter manufacturer was contacted and asked if they recommended the new clutch assembly be

installed on the helicopter. A representative from the manufacturer said they did not, and advise

those seeking a new clutch assembly that a new -3 model is what is available. She said the -3

clutch assembly is FAA approved. She said the older -2 type clutch assembly is still a usable item

for the helicopter."

Re: Formsprag clutch

My ship had a -2. Last February I installed a brand new -3 into Dave Matthews' ship. He got the new -3 clutch from Harold, still in the original box.

I think the way the NTSB report is worded...what's being conveyed, is that the factory does not feel it needs to be made mandatory in the form of an AD to remove all -2's and change them to -3's.

I have never seen the "innards" of either of the two models of the clutc, but I bet the -3 is TOTALLY different inside than the -2.

If I had a ship with a -2 right now, I would definitely want to have the innards "mic'd" for wear to make sure this wasn't gonna happen to me. I'm not sure how you could legally get this done. I think I remember Formsprag saying they wouldn't do it. I don't think the factory will do it. I just know that I'd be a little nervous flying on a -2 unless I had personally been THE ONE who had 1st hand knowledge that it HAD been lubed with the Lubriplate Aero grease, often, ever since new.

Even though I'm not sure it's legal, I feel it would be prudent safety-wiser to disassemble, measure, and catalog all of the parts in your clutch, and compare them to wear limits from the manufacturer.

I'm not advising anyone to do this. I am just thinking out loud!

I think the way the NTSB report is worded...what's being conveyed, is that the factory does not feel it needs to be made mandatory in the form of an AD to remove all -2's and change them to -3's.

I have never seen the "innards" of either of the two models of the clutc, but I bet the -3 is TOTALLY different inside than the -2.

If I had a ship with a -2 right now, I would definitely want to have the innards "mic'd" for wear to make sure this wasn't gonna happen to me. I'm not sure how you could legally get this done. I think I remember Formsprag saying they wouldn't do it. I don't think the factory will do it. I just know that I'd be a little nervous flying on a -2 unless I had personally been THE ONE who had 1st hand knowledge that it HAD been lubed with the Lubriplate Aero grease, often, ever since new.

Even though I'm not sure it's legal, I feel it would be prudent safety-wiser to disassemble, measure, and catalog all of the parts in your clutch, and compare them to wear limits from the manufacturer.

I'm not advising anyone to do this. I am just thinking out loud!

YHO-3BR Pilots International

Re: Formsprag clutch

"I think the way the NTSB report is worded...what's being conveyed, is that the factory does not feel it needs to be made mandatory in the form of an AD to remove all -2's and change them to -3's."

That's exactly right and what I was trying to point out. The factory at one time apparently did the inspection as did Formsprag. It's probably not rocket science(but as in all of Aviation the consequence of even simple mistakes can be deadly) to inspect and refurbish these things if you can get the parts. The actual time life of them is a hefty 2500 hours with a 600 hour "inspection"(not called out in the type certificate data sheet but in the manual I think). I'd love to see them side by side to compare them.

By the way how long did it take you to change the Formsprag clutch?

That's exactly right and what I was trying to point out. The factory at one time apparently did the inspection as did Formsprag. It's probably not rocket science(but as in all of Aviation the consequence of even simple mistakes can be deadly) to inspect and refurbish these things if you can get the parts. The actual time life of them is a hefty 2500 hours with a 600 hour "inspection"(not called out in the type certificate data sheet but in the manual I think). I'd love to see them side by side to compare them.

By the way how long did it take you to change the Formsprag clutch?

Re: Formsprag clutch

One point to make is the fact that the FS Clutch did not cause anything to make the aircraft roll over or cause low rotor RPM or anything like that. I guess if it is going to fail, I would rather have it fail disengaging instead of staying engaged to an engine that quit.

Either way, probably a good idea to look at the one you have and install a -3 if you have any doubts.

Either way, probably a good idea to look at the one you have and install a -3 if you have any doubts.

If your wings aren't turning, they are broken and you had better get them fixed....

Re: Formsprag clutch

I did it in about 6 hrs. I hoisted the rotor system/cooling fans/transmission/aft mount as a single unit, straight up 1 foot. Then it's real easy to unbolt everything around the clutch. Check (or maybe even replace) all the 1/4" drive bolts and the "banjo" straps. and the rag coupling if needed. There's another thread where all 3 banjo straps broke into! I think they were installed wrong and I don't think that ship was in the air when it happened.

I suppose you COULD do it without disassembling the centrifugal clutch but if I were you, I'd take IT apart and inspect all the pieces too. Clean and strip all paint from the spring and tube ring, and lube it lightly with high temp grease so it won't stick when you shutdown, lest you wind your blades into a pretzel.

I suppose you COULD do it without disassembling the centrifugal clutch but if I were you, I'd take IT apart and inspect all the pieces too. Clean and strip all paint from the spring and tube ring, and lube it lightly with high temp grease so it won't stick when you shutdown, lest you wind your blades into a pretzel.

YHO-3BR Pilots International

Re: Formsprag clutch

Hi EIGHT FIVE UNIFORM,

I hate to even think of the situations I've been in where, If my overrunning clutch had failed in the DRIVE DIRECTION, I would not be here.

I hate to even think of the situations I've been in where, If my overrunning clutch had failed in the DRIVE DIRECTION, I would not be here.

YHO-3BR Pilots International

Re: Formsprag clutch

Oh... and Seneca... I THINK the 300 hour inspection on the -2's involved totally replacing all the wearing parts in the housing. I don't think it ever involved putting used sprag pieces back in if they were within limits.

I had more than one notable person in Brantly circles tell me that the wearing parts inside the -2 housing may very well be an off-the-shelf item. Winkey Winkey! Mine always worked perfectly. I never touched it except to lube it. David Matthews' -2 timed out at 300 and he bought that NEW -3 from Mr. Jenkins. David didn't even consider rebuilding his -2, even if parts could be found.

I had more than one notable person in Brantly circles tell me that the wearing parts inside the -2 housing may very well be an off-the-shelf item. Winkey Winkey! Mine always worked perfectly. I never touched it except to lube it. David Matthews' -2 timed out at 300 and he bought that NEW -3 from Mr. Jenkins. David didn't even consider rebuilding his -2, even if parts could be found.

YHO-3BR Pilots International

Re: Formsprag clutch

Bryan,

You've got a PM.

You've got a PM.

Re: Formsprag clutch

So is there an option for those of us who have the -2 sprag? Can we get the 600hr done by Formsprag or Brantly right now?

Semper ubi sub ubi

Re: Formsprag clutch

I believe, for folks who have a -2 in their ship, AND if your -2 doesn't have an entry in your Airframe Logbook, that it has been "inspected" wthin the last 300 hours (I'm pretty sure Brantly Maintenance Data says 300 on -2's) ...

...the only options are Buy a brand new -3 from Brantly, if they have one, or find a used -2 or -3 from someone who has had a rollover etc., or contact Harold for a used -2 or -3 with a yellow tag.

...the only options are Buy a brand new -3 from Brantly, if they have one, or find a used -2 or -3 from someone who has had a rollover etc., or contact Harold for a used -2 or -3 with a yellow tag.

YHO-3BR Pilots International

-

Mark McDaniel

- Posts: 7

- Joined: Tue Aug 11, 2009 9:20 am

Re: Formsprag clutch

Bryon,

The manual says 600hrs for inspection. Formsprag nor Brantly will do inspections and to add salt to the wound they cost $5000.00.

Sorry, Mark McDaniel

The manual says 600hrs for inspection. Formsprag nor Brantly will do inspections and to add salt to the wound they cost $5000.00.

Sorry, Mark McDaniel

Re: Formsprag clutch

Wow! And I thought the 1200 hour blade grips on the Bell 47 that cost $6000 was alot of money. $5000 for that overrunning clutch is ridiculous. It makes you wonder if NEW parts will be available in the future and at what costs?

If your wings aren't turning, they are broken and you had better get them fixed....

Re: Formsprag clutch

To recap when I called Formsprag they had no clutches and hadn't sold one since the 70's according to the guy I talked to. He was cooperative and said he'd research further and get back with me but haven't heard anything. Brantly has not done the inspection for at least 14 years(maybe longer) and Formsprag hasn't done any in many years either it seems.

So how did they build those new 2000 s/n ships? Had to be NOS(new old surplus I guess).

It is a 600 hr inspection for both the -2 and the -3 from what I've read. The actual life limit is 2500 hours total.

By the way the Chinese are coming tomorrow(I called the factory today) and I hope we have some positive news coming forth. Even should the Brantly become orphaned it would be viable for many, many years thanks to a loyal group of owners. I'm hoping for much better though!

So how did they build those new 2000 s/n ships? Had to be NOS(new old surplus I guess).

It is a 600 hr inspection for both the -2 and the -3 from what I've read. The actual life limit is 2500 hours total.

By the way the Chinese are coming tomorrow(I called the factory today) and I hope we have some positive news coming forth. Even should the Brantly become orphaned it would be viable for many, many years thanks to a loyal group of owners. I'm hoping for much better though!

Re: Formsprag clutch

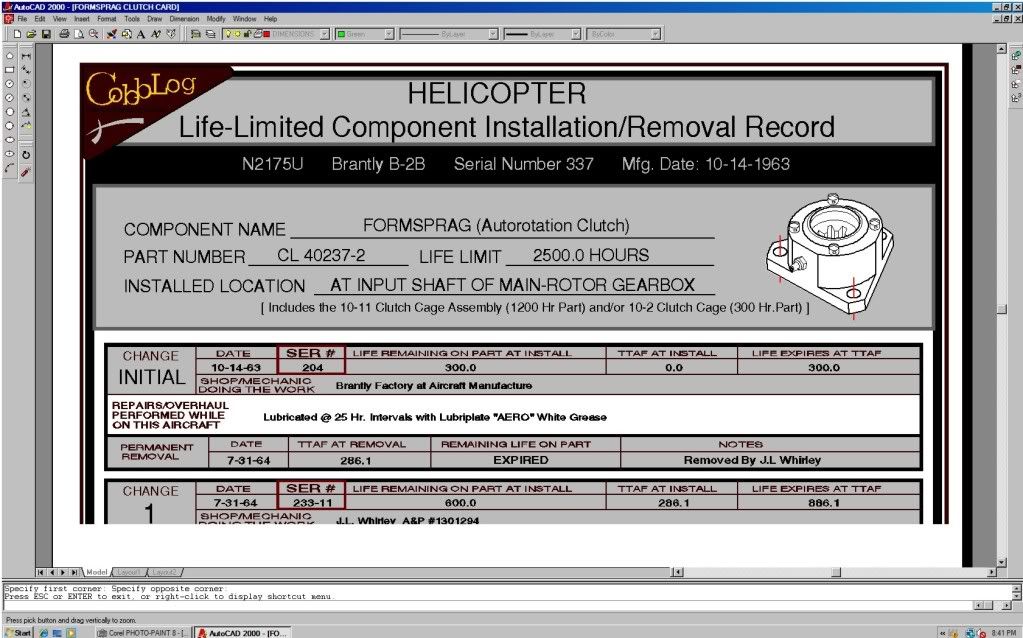

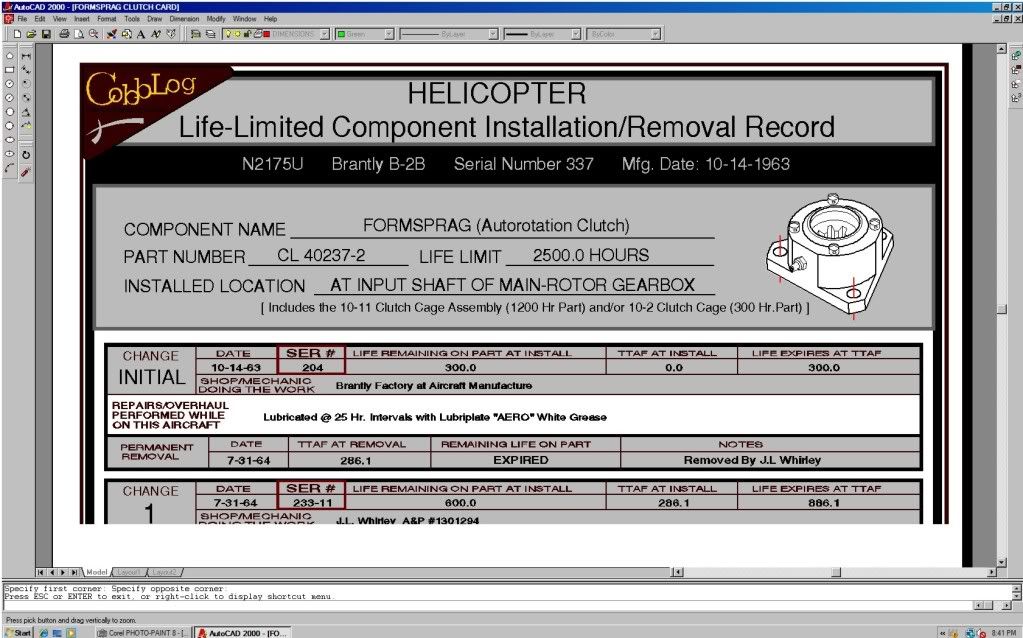

I don't remember what the specific issues/parts were that determined 300 or 600 hours for the inspection.

It's been a few years since I was deep into it.

When I drew up my CobbLOG Maintenance cards, I put some P/N's on the card for the internal

components and listed the life of those parts. Don't know how much of a clue this is but I KNOW

that for me to have put the hours on the card, I would have found it in writing and had it verified by

Doyle at the factory. He helped me a lot!

It's been a few years since I was deep into it.

When I drew up my CobbLOG Maintenance cards, I put some P/N's on the card for the internal

components and listed the life of those parts. Don't know how much of a clue this is but I KNOW

that for me to have put the hours on the card, I would have found it in writing and had it verified by

Doyle at the factory. He helped me a lot!

YHO-3BR Pilots International

Re: Formsprag clutch

I did some research to possibly assist. I think the answer to some of the questions regarding the 300 / 600 hour inspection can be found in Service Letter #26. The CL40237 replaced the roller-ramp type clutch part # B2-10-11 (which have a 100 hour tear down and inspection). As for the CL40237 the service letter states it has a 300 hour inspection and refers you to the B-2 Maintenance manual. So in checking the maintenance manual it does mention the 300 hour and states that "until service experience establishes a longer interval the overrunning clutch must be returned for engineering evaluation, inspection and overahaul as required at each 300 hour interval." Now, to the current revision of the B-2B Manual. The same statement is listed but it says "at each 600 hour interval" So based upon what I read, using the latest manuals then through "service experience" they must have increased the inspection to 600 hours.