Oil leaks

Moderator: Paul Sehorne

Oil leaks

Let's talk oil leaks. It seems the way the magneto case bolts to the accessory case and crankcase that it's almost destined to leak. Of course there's also plenty of other places for aircraft engines to leak-push rod tube seals, rocker box covers, fuel pump drive shaft seals, cylinder bases, crankcase thru bolts, external exhaust valve oil tubes, etc. So does your Brantly leave a spot on the hangar floor? Where have you found leaks? I hate the thoughts of pulling the engine just to fix a oil leak!!!!!!!!!

Re: Oil leaks

HI ED most brantlys i have seen leak oil. I believe it is mostly on how the person did the over haul.using the wrong type sealers and and some cases no sealer at all.. good judgment of type of sealer used is important.. each one is different and where to use it.your right they can leak from any place tho.knock on wood mine does not leak a drop....it is nice that I can inspect every thing and see it clearly with out oil on things.oil on things can also wear things out like wash out sealed bearings if soaks it to much and oil collects dirt which in return wears components out prematurely.. but any how good point.....really glad to see your flying now

Re: Oil leaks

Thanks Tom. Worked on it almost all day today trying to get it drier. Changed the right side rocker box covers to the red rubber gaskets(that was as usual by far the hardest job of changing rocker box cover gaskets I've ever experienced lol). I'm still chasing the oil leak though as I just haven't seen a leak that I think is making my hanger oil spot. I'm sure hoping to get it back together tomorrow to fly some more but I already have a fixed wing cross country scheduled-I just can't get excited about that with the helicopter sitting there waiting  !

!

Last edited by seneca2e on Sat Dec 22, 2012 9:51 pm, edited 1 time in total.

Re: Oil leaks

ED when I first got mine. I had a oil leak and found it was the oil pressure line on back of engine that goes to bulk head on fire wall.it had a little pine hole from rubbing so replaced that clamped down good and no leaks might be something to check

Re: Oil leaks

Thanks Tom I'll go back and check that very carefully. I've suspected chafing on that oil pressure line all along as you suggest but inspecting every inch of that thing is very hard as you know. The part from the elbow where it first picks up the oil pressure and then disappears is very hard to see. The area you're talking about I think I can double check okay so I'll do that today.

Re: Oil leaks

OK one more thing I for got was my Hobbs hr meter switch was leaking 2 that's why i had old post looking for one....glad your posting all this it does help others plus makes the for more active forum...

Re: Oil leaks

ED,

I'm not sure about other ships but when I had my engine out, I took the opportunity to eliminate leaks. I had every book that Lycoming published and I followed them to the letter. I was 100% certain it would be bone dry after it was put back in.

I was so disappointed. After flying, oil would be splattered around. Not a lot, but enough to disappoint me terribly.

I traced it and it seemed to be coming out the joint where the exhaust pipes slid onto the little stub pipes that bolt on to the exhaust outlets.

Then I noticed that my pretty chalky white exhaust outlets would turn black if I let the engine for long periods.

I modified my warm up to avoid all low throttle with rotor stopped. I'd engage the rotor and go to about 1500RPM for warmup. Then when I landed, I'd cool down at 1500 and when CHT cooled, I'd roll off throttle and kill mags immediately.

This totally eliminated the oil splatter and the white pipes returned,

All I can figure? The oil squirt on the exhaust valve stems was making its way into the exhaust port at idle and there wasn't enough heat to burn it away, so it escaped? That's just an opinion. Nothing to back it up.

I'm not sure about other ships but when I had my engine out, I took the opportunity to eliminate leaks. I had every book that Lycoming published and I followed them to the letter. I was 100% certain it would be bone dry after it was put back in.

I was so disappointed. After flying, oil would be splattered around. Not a lot, but enough to disappoint me terribly.

I traced it and it seemed to be coming out the joint where the exhaust pipes slid onto the little stub pipes that bolt on to the exhaust outlets.

Then I noticed that my pretty chalky white exhaust outlets would turn black if I let the engine for long periods.

I modified my warm up to avoid all low throttle with rotor stopped. I'd engage the rotor and go to about 1500RPM for warmup. Then when I landed, I'd cool down at 1500 and when CHT cooled, I'd roll off throttle and kill mags immediately.

This totally eliminated the oil splatter and the white pipes returned,

All I can figure? The oil squirt on the exhaust valve stems was making its way into the exhaust port at idle and there wasn't enough heat to burn it away, so it escaped? That's just an opinion. Nothing to back it up.

YHO-3BR Pilots International

Re: Oil leaks

Good point Bryan. I actually use 2000 rpm to cool down and warm up(after the oil pressure is up) since it's above the upper limit of where the centrifugal clutch is suppose to be 100% locked up(1700 rpm). I then roll the throttle off and kill it with the mixture. My pipes look great but I still have some oil on external exhaust cooling fins near the exhaust pipe and several other places. It's VERY rare to have a 100% dry engine in any aircraft little on a helicopter with a vertical engine but I have a little too much oil leakage right now to suit me. It's not dangerous but the only way to fix it is probably to pull the engine and I really don't won't to do that just yet. I'm still looking for the major leak but no joy so far.

Re: Oil leaks

OK. You are right on the 1700. I was thinking clutch in by 1200 but that was the Mini-500. I'm certain I didn't warm-up and cool down in the clutch-slip zone. I tried to avoid that heat as much as possible. It warps the friction plates badly. Dave Matthews' plates were warped 3/4 to 1" when placed on a flat surface.

YHO-3BR Pilots International

Re: Oil leaks

What kind of oil breather line(crankcase ventilation) do some of you have installed? Mine is a metal semi flexible conduit type which is somewhat porous on it's journey to the outside dump out the left side. Thinking of replacing it with some Mil 6000 hose or wrapping it with hi temp(600 degrees) rubber tape. Also going to replace all the oil drain back tube hoses that connect back to the magneto accessory case with Mil 6000 hose.

Re: Oil leaks

My crankcase hose was just a rubber hose out through the sleeve in the side of the fuse. It was serviceable so I put the old one back on.

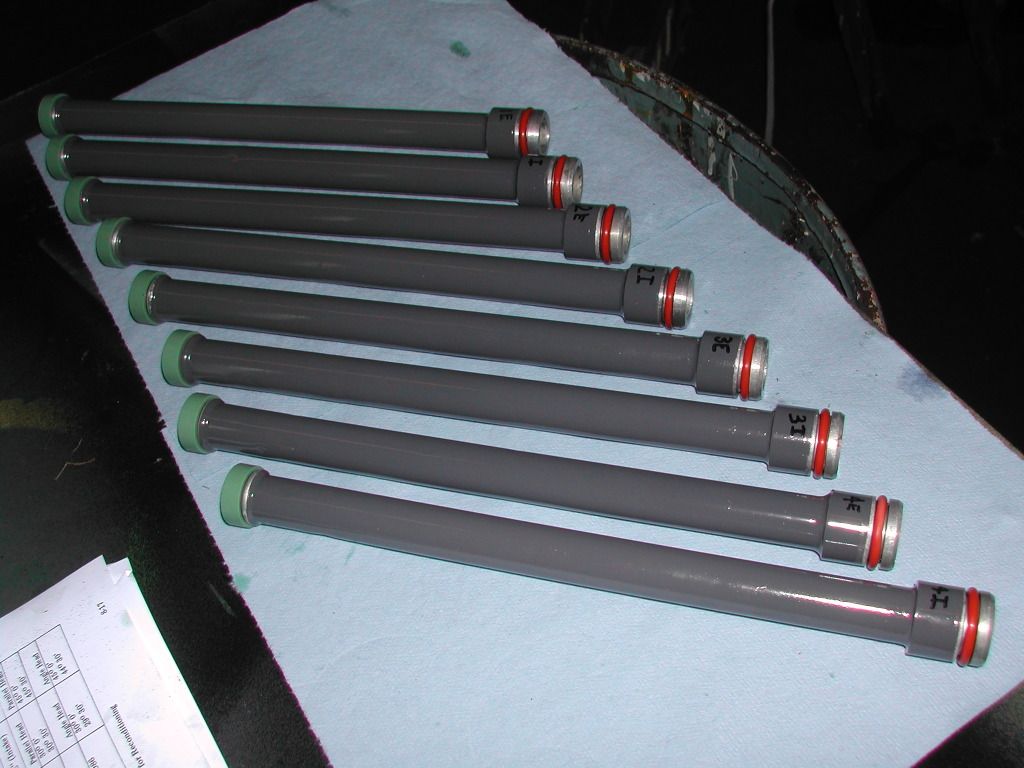

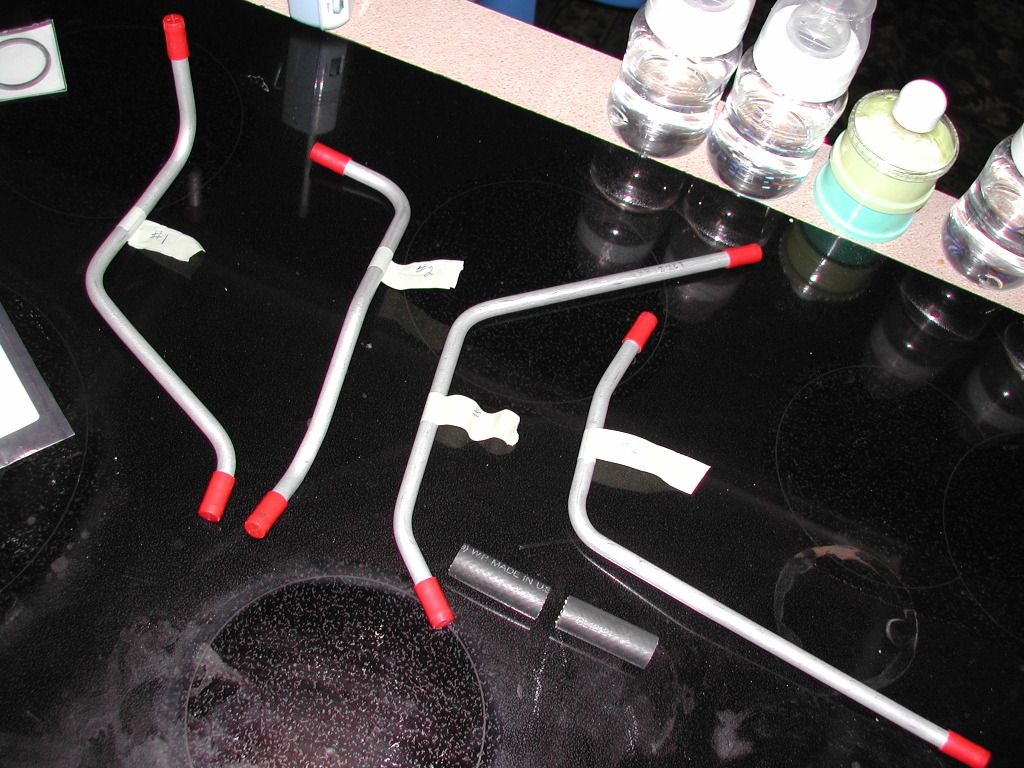

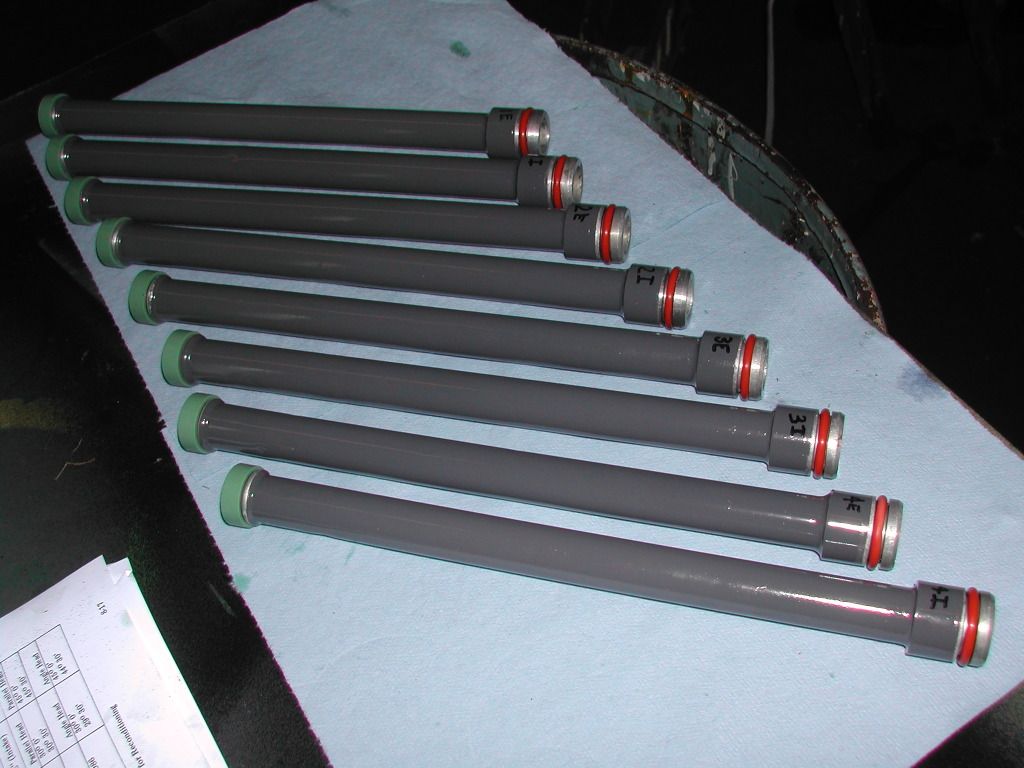

My aluminum return lines were in bad shape with kinks and pinholes, and the rubber pieces were swelled up and leaking. Doyle sent me an $800 set of Lycoming ones for my FAA Repair Center to use as patterns to fab new ones. Then I just returned the $800 set back to Doyle with no charge.

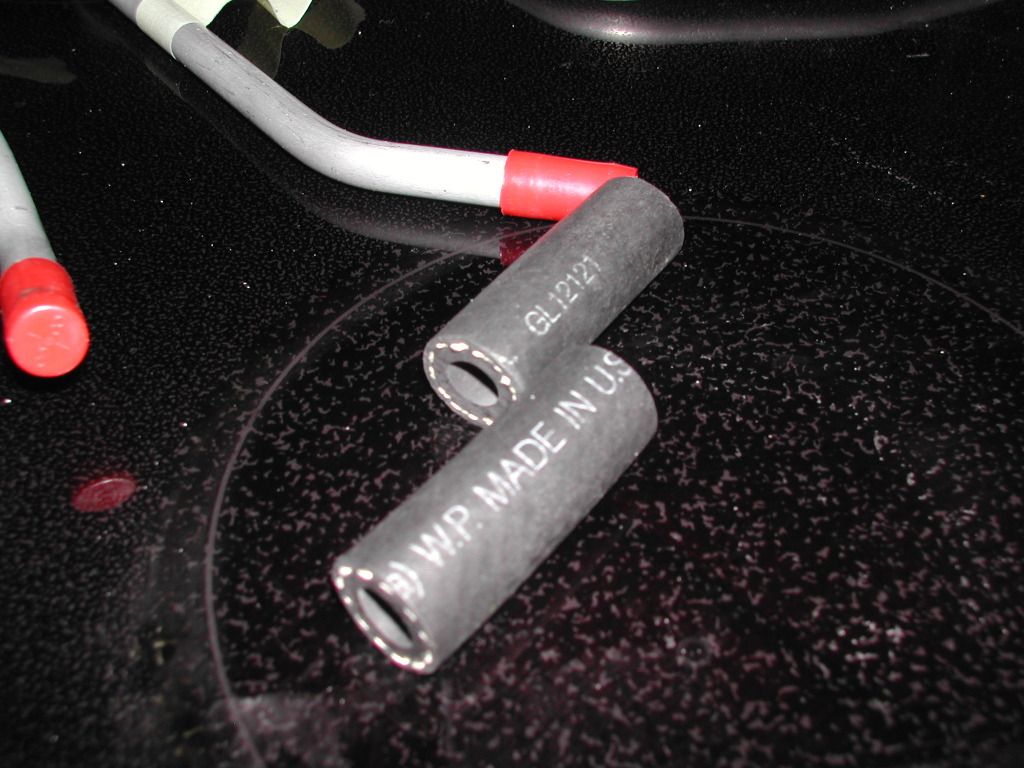

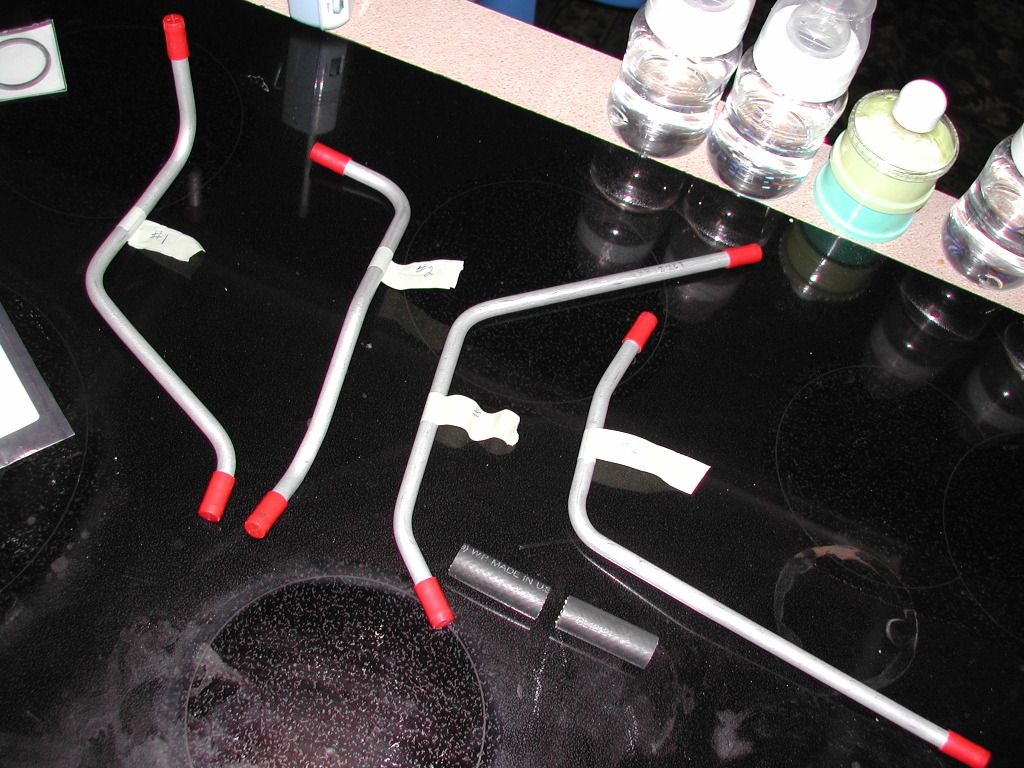

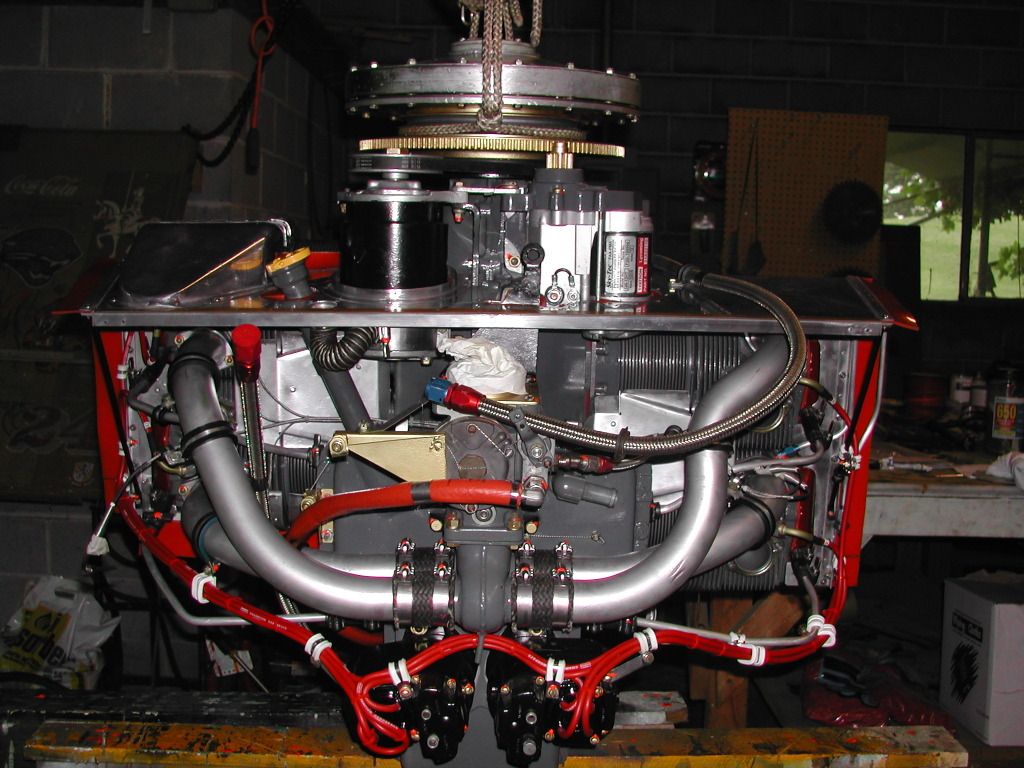

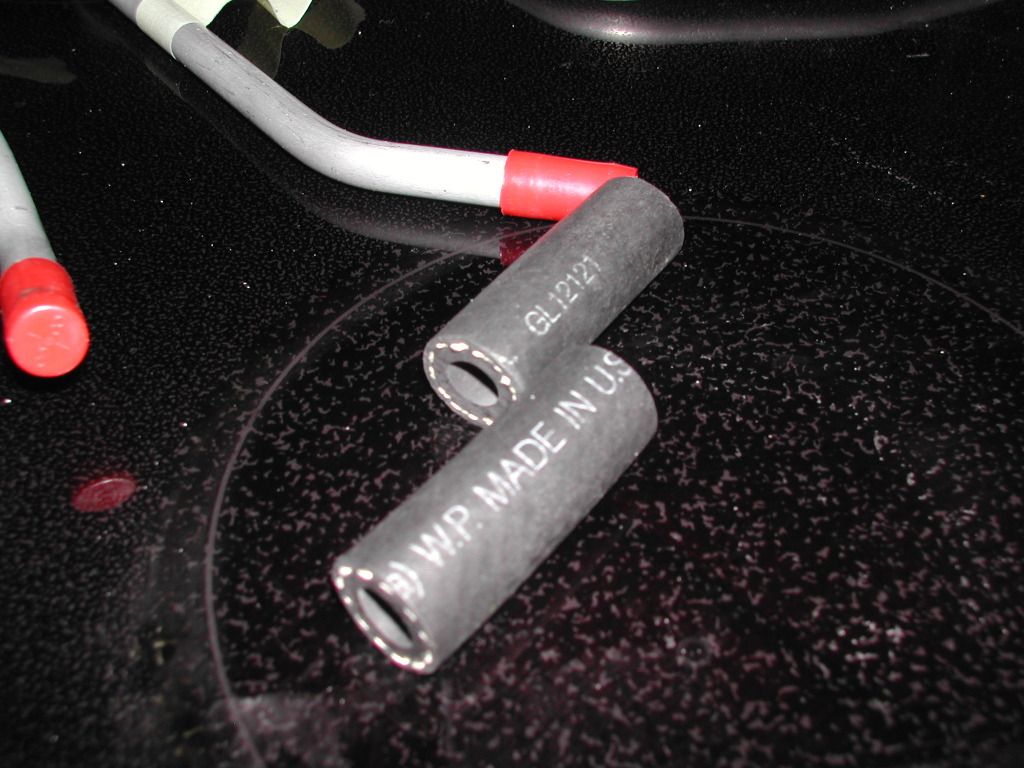

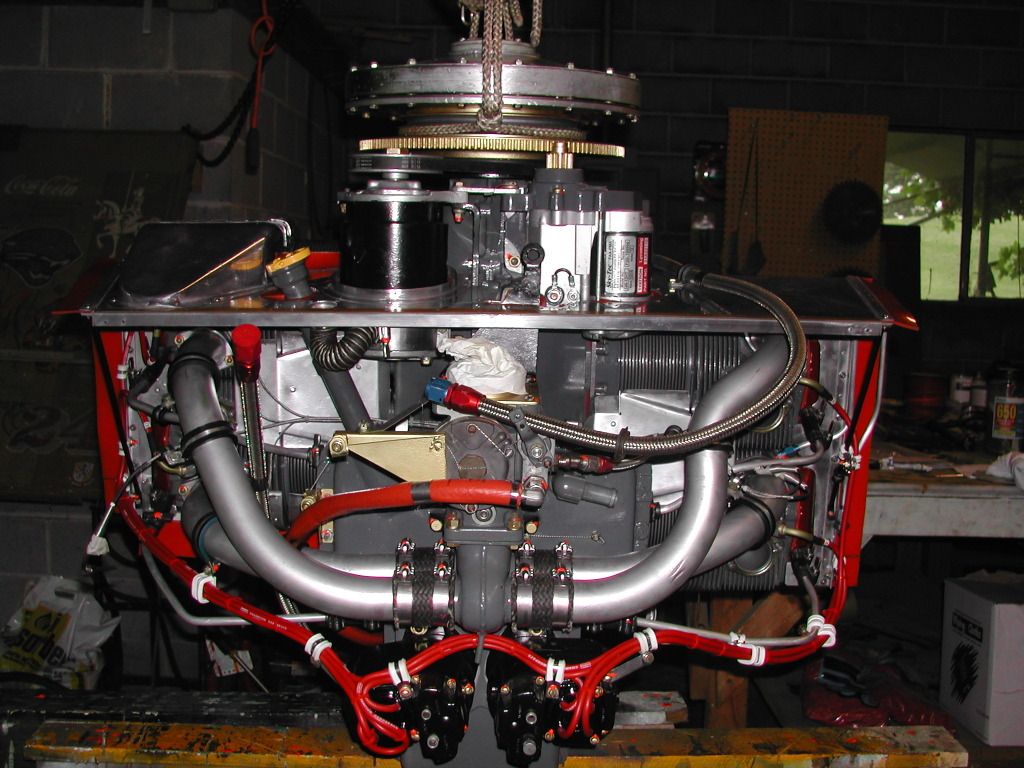

In the 4th pick you can see that my engine was getting oil splattered all around on the cylinders near the exhaust ports only. I replaced the o-rings on the pushrod tubes as shown in the 5th pic. That may have been where some of mine was coming from.

My aluminum return lines were in bad shape with kinks and pinholes, and the rubber pieces were swelled up and leaking. Doyle sent me an $800 set of Lycoming ones for my FAA Repair Center to use as patterns to fab new ones. Then I just returned the $800 set back to Doyle with no charge.

In the 4th pick you can see that my engine was getting oil splattered all around on the cylinders near the exhaust ports only. I replaced the o-rings on the pushrod tubes as shown in the 5th pic. That may have been where some of mine was coming from.

YHO-3BR Pilots International

Re: Oil leaks

As usual your documentation and pictures are simply superb. I always intend to take a lot of pictures but get in a hurry and just fix it. The value to not only yourself but someone down the road of doing it the way you do is immense. I got the mil 6000 hose in today to replace the drain back tubes and I'll pressure check the aluminum lines as well. I'm definitely getting oil in that area. I'm not delusional enough to think I'm going to get this thing bone dry but want to get it fairly good.

Re: Oil leaks

Interesting difference in your oil drain back tubes from mine. Mine collect together from the two rocker box covers on each side(aluminum tubes form a two into one) and then those go the magneto accessory case on each respective side. Also yours has a hole in the sheet metal for the cooling hose to the generator where mine does not. Minor differences. At any rate I changed all the flexbile hoses there and it's all dried up but those were not the leak I'm after. The bottom of the engine is just soooooo hard to see. I've even tried a Borescope but just can't see where it's coming from. I'm betting it's the oil pressure line or oil line to the oil cooler on left side of engine but I just can't verify it. I dread the thoughts of pulling that darn engine to find it!

Re: Oil leaks

The cooling hose was one of my stupid brain farts. I thought that would be a deluxe way to do it but I wound up capping it off. The starter has inflow behind the pulley. It flows OUT the 1" tube on the LOW PRESSURE side of the baffle. The way I had it in the picture...no cooling would take place because I had 2 inlets and no outlet.

YHO-3BR Pilots International

Re: Oil leaks

starter=generator right? So as not to confuse anyone(including me  !

!